We know from scientific research that the brain is susceptible to rotation. In the event of an impact, the helmet technology provided by a Mips® safety system is intended to help reduce the effects of rotational energy on the head by enabling a relative movement between the head and helmet.

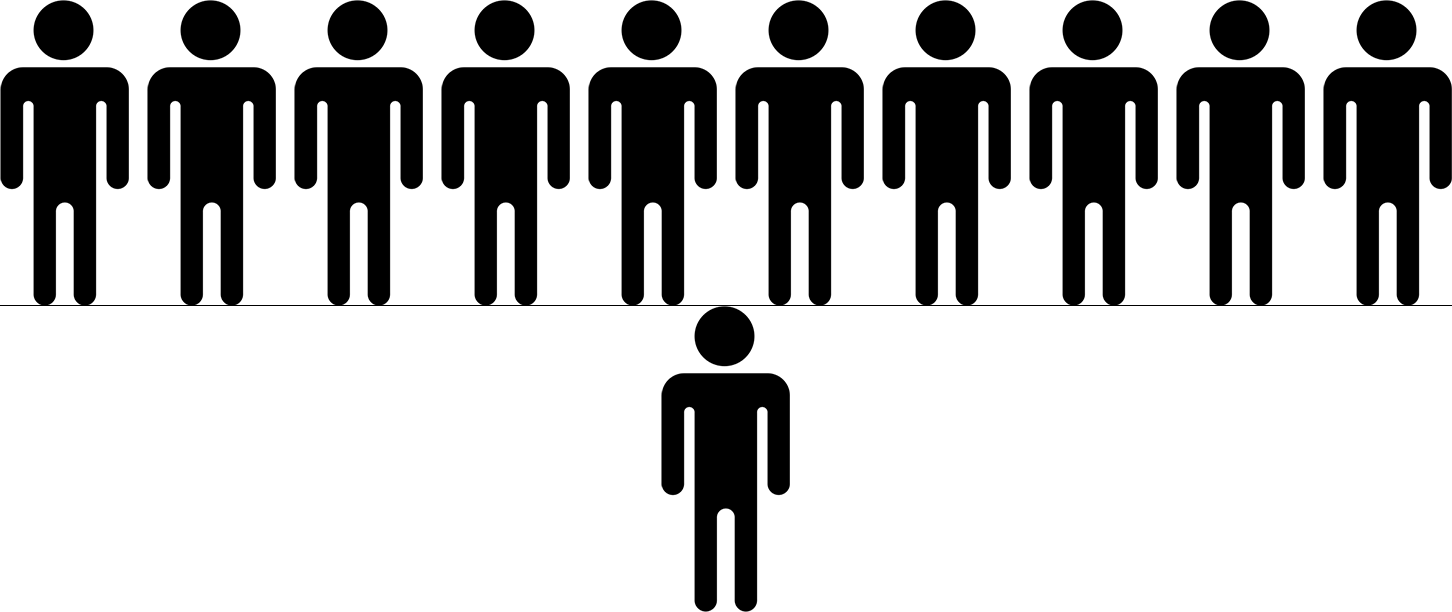

When such an impact occurs the forces that build up between the head and helmet are immense. These forces can be compared to the weight of up to 10 people suddenly standing on your head. Under such high pressure, the friction between the head and the helmet makes it hard for the helmet to move – even if the straps are slightly loose or if the helmet doesn’t have a properly secure fit as recommended by the manufacturer. But a Mips® low-friction layer inside a helmet can still allow Omni-directional movement of 10-15mm when that high load occurs.

Most helmets certified by industry-accepted safety standards can reduce the energy of a straight, linear impact. But when it comes to angled impacts, which is the most common type of impact from crashes or falls, a Mips® safety system-equipped helmet can also help reduce harmful rotational energy.

Think about a fall on a slippery slope: If you fall and hit your head (or helmet), you will most likely continue in the same direction as before the fall. Alternatively, consider a similar fall on high-friction asphalt– a very different scenario. When your helmet hits the ground, there will most likely be a sudden stop and a rotation of the helmet. Mips® safety system intends to redirect that energy away from the head.

When a manufacturer decides to create a helmet equipped with a Mips® safety system, they work closely with the engineers at Mips to tailor the system to each particular helmet model and size. Once the design has been set, helmets in all sizes are sent for testing approval of the design of this specific Mips® safety system at our state-of-the-art test lab in Sweden. We impact-test the same helmet model (and size), comparing helmets equipped with the Mips® safety system to ones without.

Our tests are performed by putting the helmet on a dummy head called Hybrid III which is equipped with accelerometers. Each test is filmed with a high-speed camera. The pulse of the acceleration is captured and sent to our computers, which simulate what happens during the impact. When we analyze the data and the film of an approved helmet, we can see that:

In summary, the difference between a helmet with and without a Mips® safety system is that a Mips® safety system allows the helmet to move 10-15mm relative to the head on certain angled impacts. Every helmet available to consumers with a Mips® safety system has passed our strict testing protocols.