How we use head forms in our helmet testing

Mips is aware of recent discussions in the media questioning the efficacy of the head forms used in our helmet testing, particularly around the presentation of something called WG11 as a rotational motion testing protocol.

We want to be clear that any reference to WG11 as a self-contained test method for rotational motion is false and misleading. WG11 is not an established test method, nor is it an established test standard, nor does it have a logo for use in the market, regardless of its appearance on helmets.

The WG11 is a completely independent working group of individuals from helmet brands and diverse academic backgrounds in Europe, all working together under the European Committee for Standardization to advocate for improved helmet testing methods.

Mips is committed to moving helmet technology forward while honoring the scientific process. We take very seriously any claims that our test methods do not meet the highest scientific standards.

The Hybrid III head form, which Mips has been using in its helmet tests, has a higher Coefficient of Friction (CoF) than the EN960 head form, meaning it’s less likely to slide past another surface easily. A helmet with Mips technology does not stop working if the CoF is low. In comparison studies, our testing data shows that this difference in CoF does not correlate with a decrease in the efficacy of the Mips system.

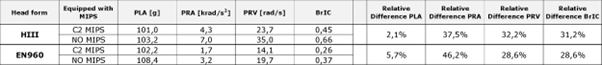

Mips conducted in-house tests with a generic bike helmet in which the helmet and head form were dropped at a speed of 6.2 meters per second against a 45-degree anvil covered with sandpaper. We used the same helmet model with and without the Mips system, comparing the reduction in the Peak Linear Acceleration (PLA), Peak Rotational Acceleration (PRA), Peak Rotational Velocity (PRV), and the Brain Injury Criteria (BrIC) value. Where PLA, PRA, PRV and BrIC all describe the forces and energy a Mips system is designed to help reduce. The values can be seen in the table below.

The results show clearly that helmets with and without the Mips system have similar reductions using the Hybrid III head form compared with the EN960 head form. The Mips system has also been evaluated in external studies where the CoF has been reduced in comparison to the Hybrid III head form (Bonin et al. 2022. https://doi.org/10.1007/s10439-022-02961-w).

Mips’ position, after years of scientific research, is that the Hybrid III head form more closely mimics the human head than the EN960, despite the difference in CoF. There are other features, like the moment of inertia, overall mass, and the compliance of the skin that influence a head form’s ability to best mimic the human head and its behavior in an impact.

At Mips, we believe that we need to take the next step beyond the EN960 head form, which was developed more than 40 years ago purely for linear impact tests. When WG11 was convened, the EN960 head form was not considered to be the best representation of the human head, especially in testing for rotational motion. At that time, the Hybrid III head form was the best candidate, but the need for additional advancements in head forms was clear. The WG11 has since decided to develop a new head form to take all aspects into account, including, mass, a moment of inertia, the centre of gravity, shape, the influence of the neck, and CoF.

Mips test methods are constantly improving based on new scientific data and understanding of real-life accident scenarios. We are also part of and influenced by the important work being done by WG11 and other standardization groups in Europe and USA. That’s part of the reason we established our technology on the Hybrid III head form and why we will start using the new WG11 head form as soon as it’s ready.

About Mips

Mips specializes in helmet-based safety and is a market leader in this field. The Mips® safety system is based on an ingredient brand model and is sold to the helmet industry worldwide. The Mips® safety system is patent protected and based on 25 years of research, testing and development in cooperation with the Royal Institute of Technology and Karolinska University Hospital in Stockholm, Sweden. The company’s headquarters are also located here, with more than 70 employees working in research and development, sales, marketing and administration, and the test center. Currently, Mips works with more than 150 helmet manufacturers, the safety system is used in over 800 models and has been integrated into 12.6 million helmets worldwide in 2021 alone. For more information, visit mipsprotection.com.

Media Contact

Marcus Lindgren, PR-Director, Mips

marcus.lindgren@mipsprotection.com