Before a Mips® safety system-enabled helmet model becomes available to consumers, it is first tested at our Swedish lab to ensure that it meets Mips safety standards

In the approval test, we drop the helmet vertically onto an impact plate covered with 80-grit sandpaper set at 45 degrees. This test relies on statistically proven real-world crash scenarios and makes for a predictable and repeatable method, which is key in any scientific work

We set the impact angle for testing at 45 degrees for several reasons. First, studies show this to be the most common impact angle in bike accidents. Second, the rotational protective properties of the helmet are under the most stress at 45 degrees.

The test impact speed is 6.2 m/s for bike helmets, horse riding helmets, and snow helmets. For motorcycle helmets and motocross helmets, the impact speed is 7.5 m/s, while for safety helmets it is 4.5 m/s.

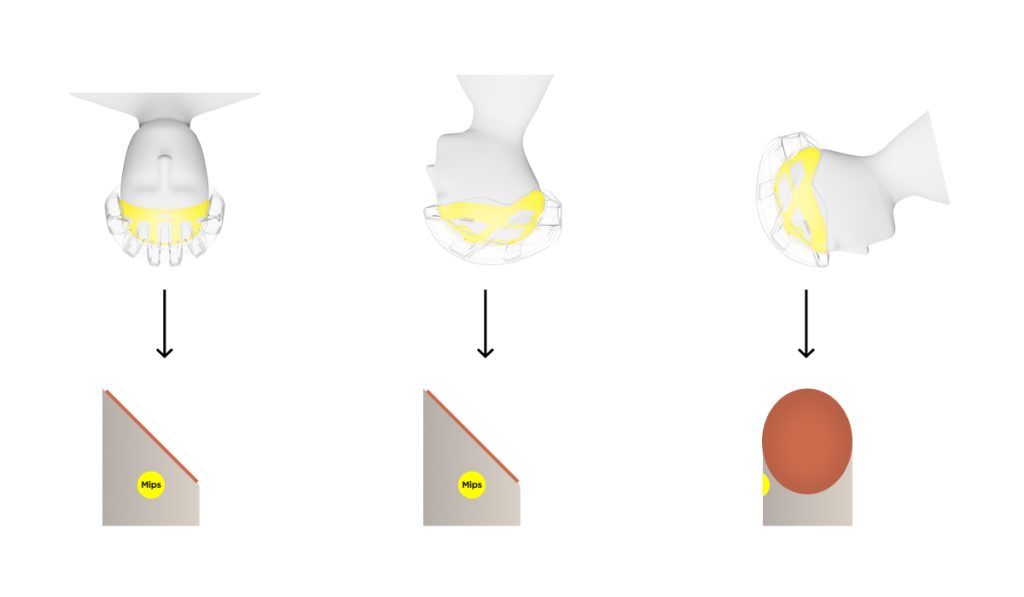

We test the helmet in three areas based on real accident data and an evaluation of the most common impact points. And we select the impact direction for each point to result in rotation around all three anatomical axes X, Y and Z.

The human head is more sensitive to rotation around the X (rear-to-front) and Z (vertical) axes compared to rotation around the Y axis (ear-to-ear).

The Mips® safety system is an omnidirectional system. developed to help reduce rotation around all axes. However, its function can vary for different impact locations due to factors such as head shape, the design of the helmet and the crash.