The Mips helmet test laboratory near Stockholm in Sweden has been in continual development for more than 25 years. This modern 300 sqm complex includes four test machines and state-of-the-art tools designed to mimic real-world impact scenarios. This gives us full control over what we are measuring.

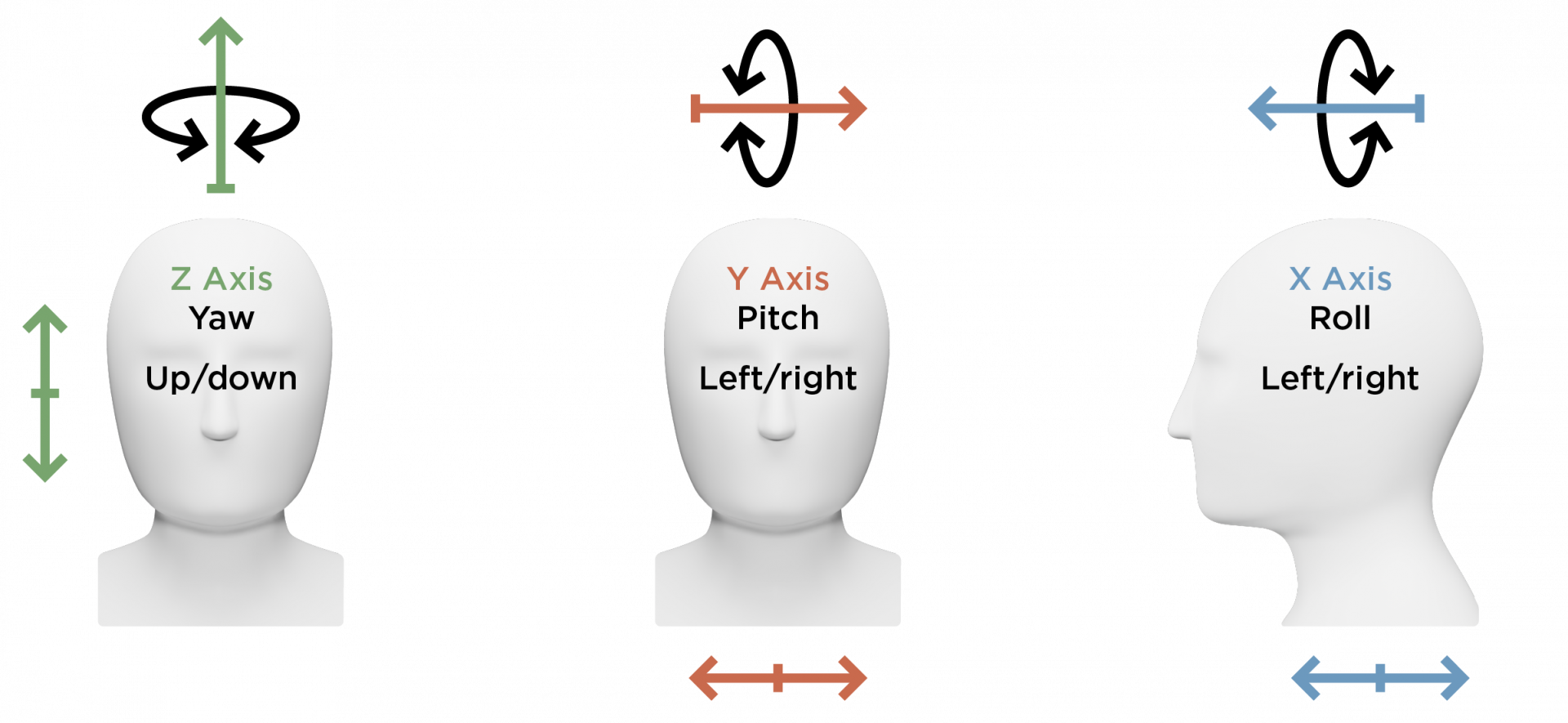

Mips measures 6DOF (six degrees of freedom) accelerations over time. DOF refers to the freedom of movement of a rigid body in three-dimensional space. Put simply, DOF measures the way objects are able to move through space.

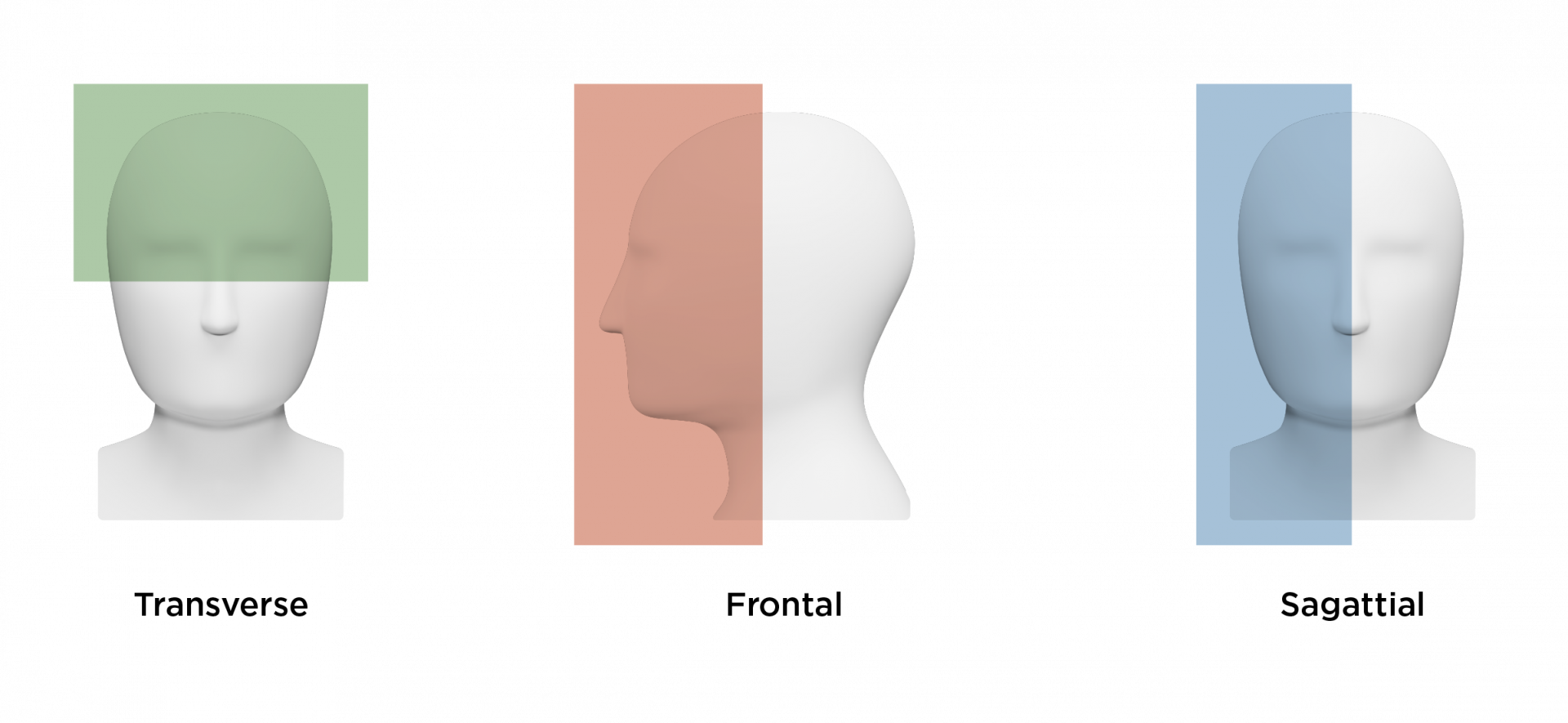

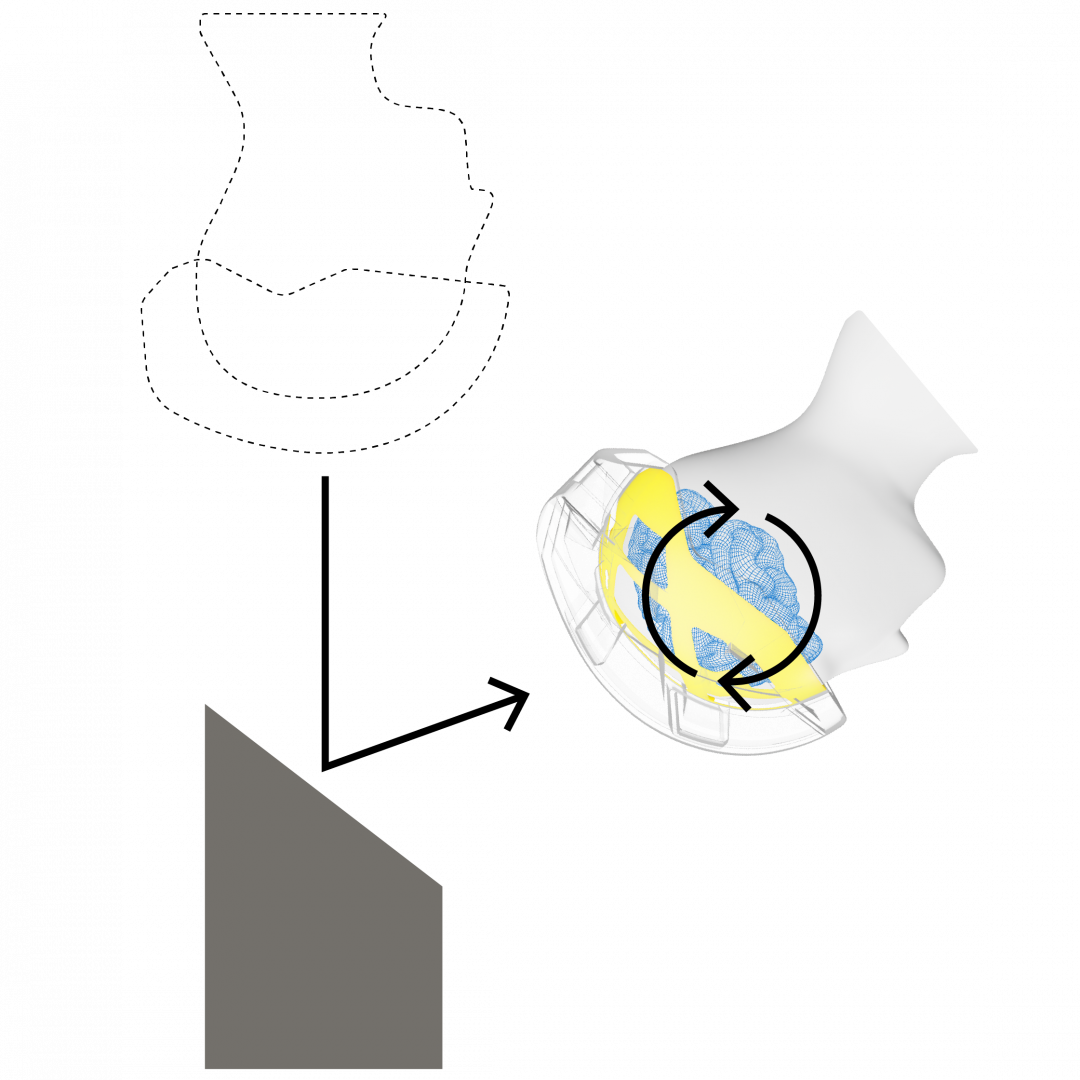

For each helmet, we test three different areas: front, lateral and pitched. Because studies show that the vast majority of head impacts from bicycle, motorcycle, equestrian and other sports accident are angled, we perform all helmets test at an angle of 45 degrees. Above all, the most important thing is to have control over the initial position of the head and the helmet during the vertical drop to the impact anvil.

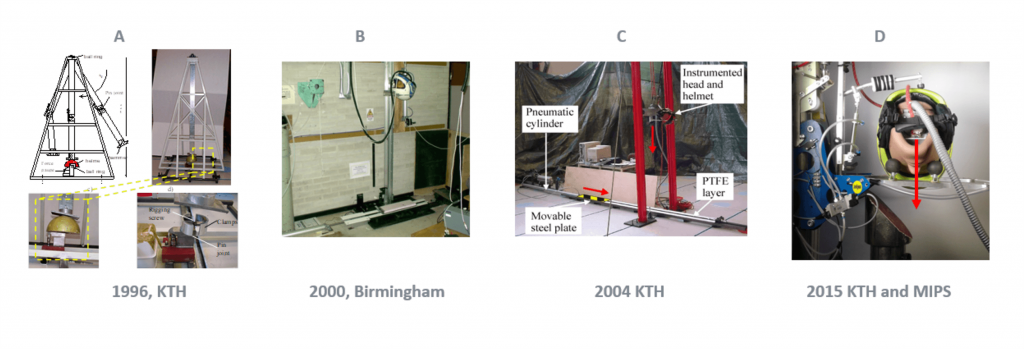

It took 15 years to develop the complete Mips test environment. Our first test machine was built in 1997, and since then it has evolved into what we use today. We developed our test methods to replicate real-life accident situations. For example, analysis of bike crash statistics shows that impacts most commonly occur at 6.0-6.5m/s (meters per second) at an angle of 45 degrees, so we test the helmets at a speed of 6.2m/s with a similar impact angle.

As a substitute for the human head, we use an experimental system called the Hybrid III. Inside the head form, a set of accelerometers measures 6DOF accelerations over time. All helmets are impacted at three different points to control the Mips® safety system function around all three anatomical axes (X, Y and Z). We test the same model of helmet, with and without a Mips safety system, in all available sizes.

Next, impact data is analyzed. These thorough tests ensure that the Mips safety system version of each helmet model can be approved according to the Mips standard.

We conducted our first test in 1996, using a pendulum to impact a spherical representation of a helmet(Figure A). This was a very premature design, but it did show that the Mips safety system could reduce the forces or torque to the head.

A: Pendulum test rig measuring the torque.

B/C: Movable plate, where the plate is accelerated by a pneumatic cylinder.

D: Helmeted head form dropped to a 45-degree impact surface. In test B-D, the head form is equipped with a nine accelerometer system [1, 2].

Several publications detail how to measure the energy absorption in an oblique impact with a significant force to the helmet. Some studies have used a spinning concrete wheel onto which helmets are dropped. Others have presented methods in which the head was dropped onto a sliding steel plate to create an oblique impact. One 2008 study presented a method that included an HIII crash test dummy neck and the option of measuring the force on the plate.

Another way of testing helmets for oblique impacts is to drop them onto an angled surface.

The main difference between impacting the movable plate and dropping the helmet onto an angled surface is the difference in the gravitation vector in relation to the normal force vector against the helmet—which could result in different outcomes for the two methods, even when testing identical helmets with the same impact speed and impact angle. The movable plate could, therefore, be more realistic in simulating a fall from a bike or a horse to the ground. However, the movable plate method has drawbacks compared to the angled surface technique because it is more complex. Also, it can be challenging to maintain a constant speed of the plate during the impact.

A third potential test method is the pneumatic linear impactor, which was first developed by Biokinetics in Canada. The linear impactor is equipped with a curved plastic surface attached to a disc made of vinyl nitrile foam, to mimic a helmet-to-helmet hit (designed for American football or ice hockey helmets).

In this test, the head form is attached to an HIII crash test dummy neck and a sled moving horizontally. The test method specifies different impact locations on the helmet, all of which result in impacts to the center of gravity in the dummy head.

Due to its simplicity and robustness, Mips uses the vertical drop to an angled impact surface method.

In current test methods, the head either falls unrestrained onto the impact surface (European test standards) or is constrained to a monorail via a rigid arm attached to the head (U.S. test standards). These two methods can be said to represent the extremes of the scale. Sitting somewhere in the middle is the normal situation, in which the neck constrains the head.

One option instead of designing a test without a neck could be to attach an experimental neck (like the HIII neck) to the vertical sled in a monorail helmet test rig. But to design an oblique test method, questions remain as to whether the neck will affect the measured translational and angular accelerations in the dummy head. It is clear that the neck restrains the head and that it will, at some time, rotate around a point in the neck, or even lower down in the thoracic region.

Earlier studies have shown that the amplitude of the angular acceleration is affected by the neck. Helmeted full body Hybrid III dummies were dropped onto an angled surface and compared to free-falling helmeted head forms. The results showed that the angular acceleration differed in amplitude by about 20 percent.

A 2001 numerical study on helmet-to-helmet impacts simulating American football accidents concluded that the neck did indeed change the characteristics of the angular acceleration when comparing impacts with and without a neck. However, the impacts in the study were close to a radial impact to the helmet, where the neck is the only cause for the rotation of the head. In other words, there was little to no tangential component in the impact.

A 2012 study showed that the angular acceleration components could differ by as much as 40 percent when comparing a helmet impact with the full body and the head only. Researchers used a Total Human Model for Safety (THUMS) and simulated an oblique impact on the lateral (temporal) portion of the helmet. They proposed changing the inertial properties of the head to compensate for the neck and the body if using only the head in an oblique impact test.

Another study in 2009 reconstructed 12 jockey accidents using MADYMO human models. Two of these were studied in detail in simulations with and without the body in a helmet-to-racetrack turf impact. The angular acceleration was increased, comparing the simulation with a complete body and a simulation with the head only. Researchers mentioned that the absence of the neck and the body might cause the direction of the acceleration to alter. This study stated that the MADYMO human body model provides an unrealistic representation of the flexibility in the vertebral joint that could have resulted in this large discrepancy.

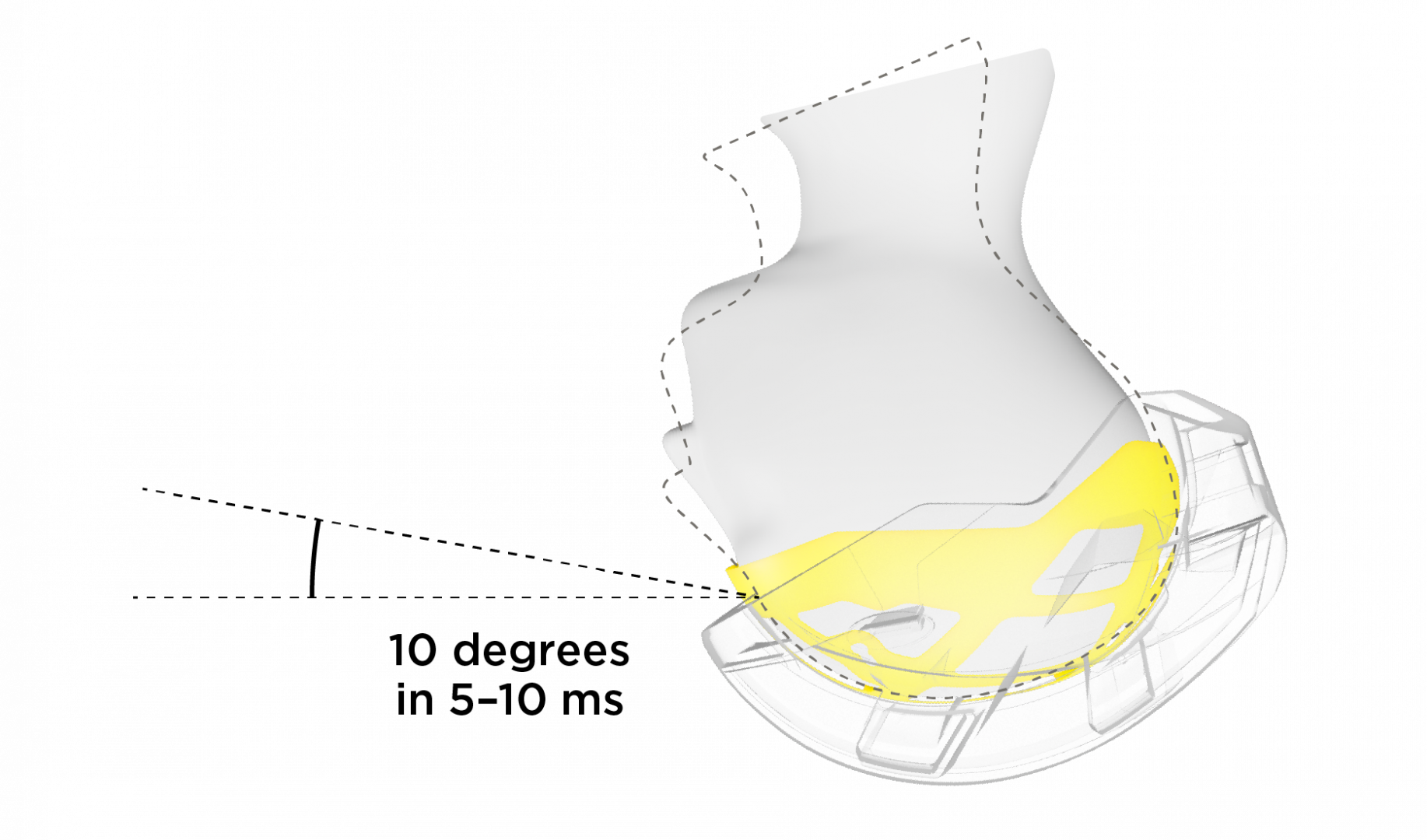

The conclusion that can be drawn is that, in general, the neck affects the motion of the head. It can also be argued that a test method could be defined with impact angles where the effect of the neck is small during the short time (5-10 milliseconds) during which the helmet comes into contact with the impacting surface.

Experimental tests on human cadavers show that the upper part of the human neck is flexible and could be seen as decoupled from the head for a certain amount of displacement or rotation. Motion in a human joint that does not result in a force or moment is defined as the neutral zone. The neutral zone in which the upper part of the neck allows the head to rotate without extensive load is in the range of 10 degrees, depending on the axis of rotation.

Thus, when we do not take muscle activity into account, the head can rotate around 10 degrees without having any effect on the kinematics in horizontal loading of the head. In a typical helmet-to-asphalt impact, the free-falling head rotates about 10 degrees during the first 10 milliseconds of impact. Based on this, one could argue there would not be sufficient time for the neck to affect the head significantly in this specific impact direction.

Other aspects of the neck/no neck questions that would need to be taken into consideration when designing a new test method are:

The conclusion is that the human neck as a boundary condition to the human head will affect the head kinematics. However, for bicycle accidents most frequently impacting the ground resulting in short (5-10 milliseconds) impacts, the neck will not affect the head kinematics so much that the neck is essential. Taking all known aspects into account, it is proposed to design the new test method without the neck.